Alpha Solder Paste OM 6106: A Comprehensive Overview

When it comes to selecting the right solder paste for your electronic assembly needs, the Alpha Solder Paste OM 6106 stands out as a reliable and high-performance option. This article delves into the details of the OM 6106 paste, exploring its composition, application, and benefits in various soldering scenarios.

Composition and Properties

The Alpha Solder Paste OM 6106 is formulated with a unique blend of fluxes, metals, and other additives that contribute to its exceptional performance. Here’s a breakdown of its key components:

| Component | Function |

|---|---|

| Flux | Facilitates the soldering process by removing oxides from the surfaces being joined. |

| Solder Metal | Forms the bond between the components being joined. |

| Additives | Enhance the paste’s rheological properties, shelf life, and overall performance. |

One of the standout features of the OM 6106 paste is its excellent wetting and spreading capabilities. This is due to the optimized blend of fluxes and metals, which ensures that the paste adheres well to the surfaces and forms a strong, reliable joint.

Application and Process

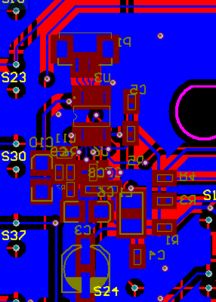

The Alpha Solder Paste OM 6106 is designed for use in a variety of electronic assembly processes, including surface mount technology (SMT), through-hole technology (THT), and reflow soldering. Here’s how to apply the paste effectively:

- Prepare the PCB: Clean the PCB thoroughly to remove any contaminants that may interfere with the soldering process.

- Apply the paste: Use a syringe or a stencil printer to apply the paste to the PCB. Ensure that the paste is evenly distributed and covers the pads.

- Place the components: Carefully place the components on the PCB, ensuring that they are aligned correctly.

- Reflow: Place the PCB in a reflow oven and heat it to the appropriate temperature for the paste and components. The paste will melt and flow, forming a strong joint between the components and the PCB.

It’s important to note that the OM 6106 paste has a wide operating temperature range, making it suitable for various reflow profiles. This flexibility allows for easy integration into existing assembly lines without the need for significant process changes.

Benefits and Advantages

Choosing the Alpha Solder Paste OM 6106 for your electronic assembly projects offers several benefits:

- Improved Joint Reliability: The paste’s excellent wetting and spreading capabilities ensure that joints are strong and reliable, even in challenging applications.

- Reduced Defect Rates: The paste’s consistent performance helps to minimize defects, such as bridging and tombstoning, resulting in higher yields.

- Extended Shelf Life: The OM 6106 paste has an extended shelf life, reducing waste and ensuring that you always have a reliable supply on hand.

- Environmental Friendly: The paste is lead-free and RoHS compliant, making it an environmentally friendly choice for your assembly projects.

Conclusion

The Alpha Solder Paste OM 6106 is a versatile and high-performance option for your electronic assembly needs. Its exceptional wetting and spreading capabilities, combined with its wide operating temperature range and environmental friendliness, make it an ideal choice for a variety of applications. By understanding the paste’s composition, application, and benefits, you can make an informed decision and ensure the success of your next assembly project.