Alpha Paste Flux OM 340: A Comprehensive Overview

Are you looking for an in-depth understanding of the Alpha Paste Flux OM 340? Look no further. This article delves into the various aspects of this product, providing you with a detailed and multi-dimensional introduction. From its composition to its applications, we’ve got you covered.

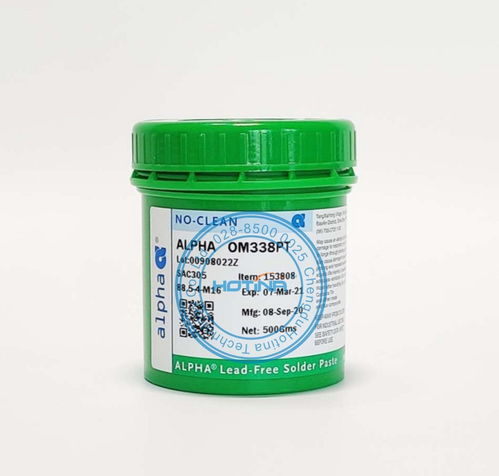

What is Alpha Paste Flux OM 340?

The Alpha Paste Flux OM 340 is a high-performance paste flux designed for use in various soldering applications. It is known for its excellent wetting properties, which make it ideal for use in electronics manufacturing, repair, and assembly.

Composition of Alpha Paste Flux OM 340

Understanding the composition of Alpha Paste Flux OM 340 is crucial in appreciating its performance. The paste flux is primarily made up of the following ingredients:

| Ingredient | Percentage |

|---|---|

| Active Flux | 60% |

| Solvent | 20% |

| Thickener | 10% |

| Other Additives | 10% |

The active flux is the key component responsible for the paste flux’s excellent wetting properties. The solvent helps in the application process, while the thickener ensures the paste remains in a paste form. The other additives are used to enhance the paste flux’s overall performance.

Applications of Alpha Paste Flux OM 340

Alpha Paste Flux OM 340 is widely used in various industries due to its superior performance. Here are some of the common applications:

- Electronic manufacturing: The paste flux is used in the assembly of electronic components, such as surface mount devices (SMDs) and through-hole components.

- Repair and maintenance: Alpha Paste Flux OM 340 is ideal for repairing and maintaining electronic devices, such as computers, smartphones, and other electronic gadgets.

- Gold and silver soldering: The paste flux is used in the soldering of gold and silver joints, thanks to its excellent wetting properties.

- Automotive industry: The paste flux is used in the assembly and repair of automotive electronic components.

Advantages of Alpha Paste Flux OM 340

Alpha Paste Flux OM 340 offers several advantages over other paste fluxes. Some of these advantages include:

- Excellent wetting properties: The paste flux ensures that the solder joints are clean and free of voids.

- High activity: The paste flux has a high activity level, which means it can remove oxides and other contaminants from the soldering surface.

- Non-corrosive: The paste flux is non-corrosive, making it safe for use on various materials, including metals and plastics.

- Easy to apply: The paste flux is easy to apply, thanks to its paste form.

How to Use Alpha Paste Flux OM 340

Using Alpha Paste Flux OM 340 is straightforward. Here’s a step-by-step guide on how to use it:

- Prepare the soldering iron and the solder wire.

- Apply a small amount of Alpha Paste Flux OM 340 to the soldering surface.

- Heat the soldering iron and touch it to the soldering surface.

- Apply the solder wire to the joint and allow it to melt and flow into the joint.

- Remove the soldering iron and allow the joint to cool and solidify.

Conclusion

Alpha Paste Flux OM 340 is a high-performance paste flux that offers numerous advantages over other paste fluxes. Its excellent wetting properties, high activity, and non-corrosive nature make it an ideal choice for various soldering applications. Whether you’re an electronics manufacturer, repair technician, or hobbyist, Alpha Paste Flux OM 340 is a valuable addition to your toolkit.