Alpha Om 353 Solder Paste: A Comprehensive Guide

When it comes to electronics manufacturing, the choice of solder paste is crucial. Alpha Om 353 solder paste has gained popularity for its exceptional performance and reliability. In this article, we will delve into the details of Alpha Om 353 solder paste, exploring its composition, application, and benefits.

Composition of Alpha Om 353 Solder Paste

Alpha Om 353 solder paste is a high-quality, lead-free solder paste designed for use in surface mount technology (SMT) applications. It is composed of fine solder particles, flux, and other additives. The solder particles are typically made of tin, silver, and copper, while the flux is a mixture of organic and inorganic compounds that helps the solder flow and wick properly.

| Component | Function |

|---|---|

| Solder Particles | Form the solder joints between components |

| Flux | Facilitates the soldering process and removes oxides from the surfaces |

| Additives | Improve the paste’s rheological properties and shelf life |

Application of Alpha Om 353 Solder Paste

Alpha Om 353 solder paste is suitable for a wide range of applications, including high-reliability electronics, automotive, and aerospace industries. Its lead-free composition makes it an ideal choice for RoHS-compliant products. Here are some common applications of Alpha Om 353 solder paste:

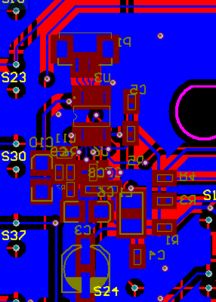

- Printed Circuit Boards (PCBs)

- Surface Mount Devices (SMDs)

- Through-Hole Components (THCs)

- High-reliability electronics

- Automotive and aerospace applications

Benefits of Alpha Om 353 Solder Paste

Alpha Om 353 solder paste offers several advantages over traditional soldering methods and other solder pastes. Here are some of the key benefits:

- Improved Reliability: The high-quality solder particles and flux in Alpha Om 353 solder paste ensure strong, durable joints that can withstand harsh environmental conditions.

- Excellent Wetting: The paste’s unique formulation promotes excellent wetting, resulting in clean, consistent joints with minimal voids.

- Wide Process Window: Alpha Om 353 solder paste has a broad process window, allowing for flexibility in temperature and time settings during the soldering process.

- RoHS Compliance: The lead-free composition of Alpha Om 353 solder paste makes it an ideal choice for RoHS-compliant products.

- Long Shelf Life: The paste has a long shelf life, ensuring that it remains effective even after prolonged storage.

How to Use Alpha Om 353 Solder Paste

Using Alpha Om 353 solder paste is straightforward. Here’s a step-by-step guide to help you get started:

- Prepare the PCB and components according to the design specifications.

- Load the Alpha Om 353 solder paste onto the stencil using a syringe or a paste printer.

- Position the stencil over the PCB and apply even pressure to transfer the paste onto the pads.

- Reflow the PCB in a reflow oven or use a hot air soldering station to melt the solder and form the joints.

- Inspect the joints under a microscope to ensure they meet the required quality standards.

Conclusion

Alpha Om 353 solder paste is a high-quality, reliable choice for electronics manufacturing. Its exceptional performance, wide process window, and RoHS compliance make it an ideal choice for a variety of applications. By understanding the composition, application, and benefits of Alpha Om 353 solder paste, you can make informed decisions to improve the quality and reliability of your electronic products.